Did you know that it is the multigrade additives that break down under stress, causing engine oils to lose viscosity at operating temperature? Do you know what multigrade additives (also known as viscosity modifiers or VI improvers) are, or why they are used in most engine oils?

Understanding the Basics of Engine Oil

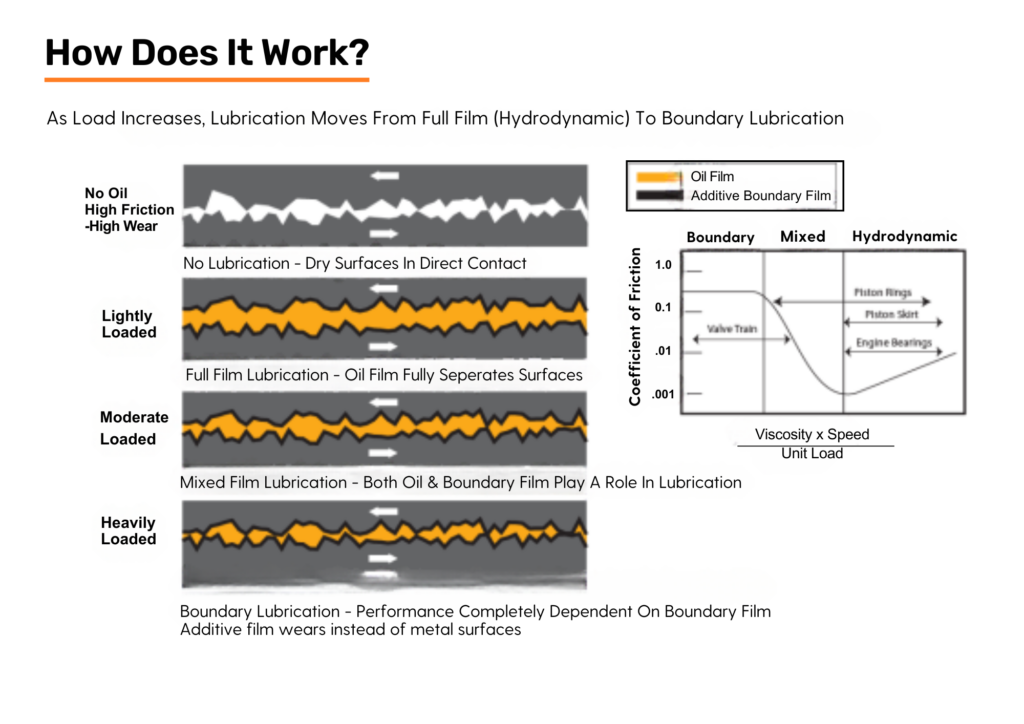

To fully understand their benefits, we need to look at the basics of oil. It’s very simple: we use oil to lubricate the moving parts of the engine and also to cool the engine. If the oil is too thin for the application, we will at best get boundary lubrication (this is when the anti-wear additives play a big role to protect the parts), or at worst, no oil at all between moving parts (metal-to-metal contact).

If the oil is too thick, it does not flow through the engine fast enough, reducing cooling efficiency. There is also a big chance that you get air in the oil when the oil pump pushes air into the oil due to lack of flow.

Before multigrade oils (sixties and earlier), it was typical to use thinner viscosity oil in the engine during winter months compared to summer months. This worked well, except that you needed to change the oil twice a year to avoid damaging the engine due to inadequate lubrication.

Using summer oil in the winter meant that it was hard for the engine to crank (I remember from my youth that we had to put a cabin heater under the engine to heat the oil before it would crank when on ski holiday in the Swedish mountains where temperatures typically dropped below -40°C). And using winter oil in the summer meant the oil was simply too thin, resulting in fluctuating oil pressure.

The Invention and Benefits of Multigrade Oils

To overcome these issues of having seasonal oils, multigrade oils were invented.

To keep it simple:

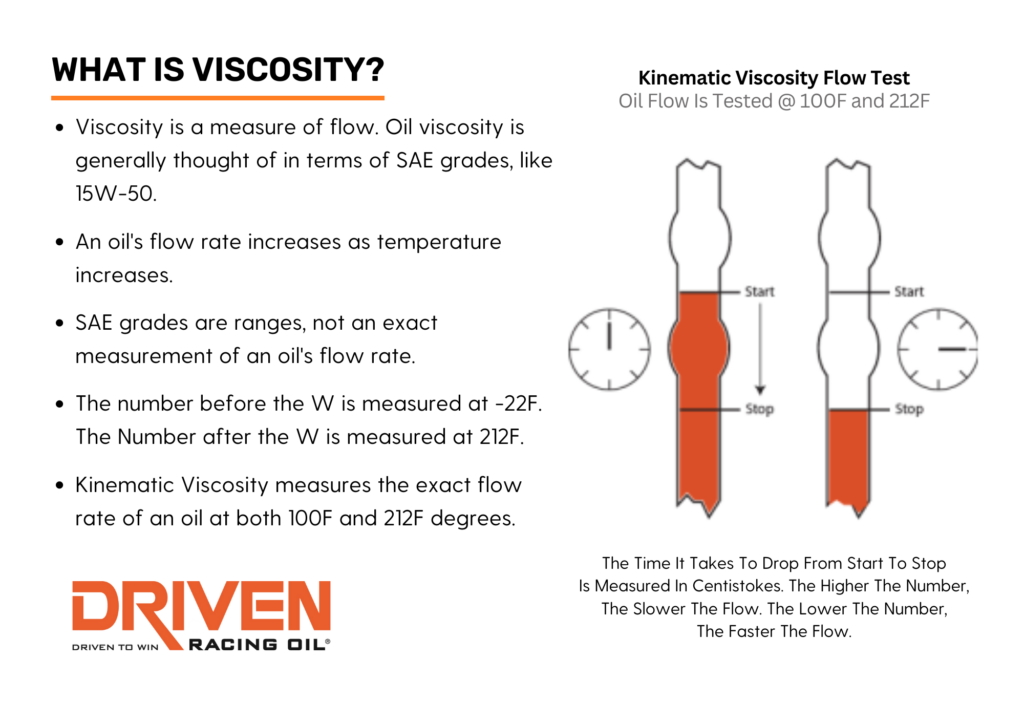

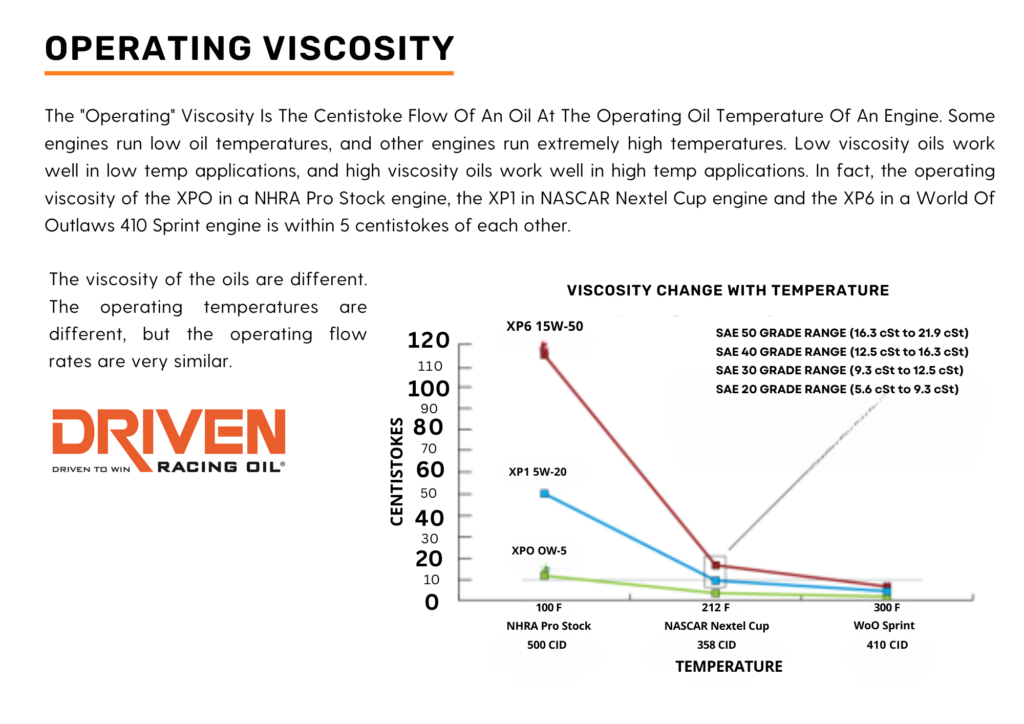

- All oils get thinner with increasing temperatures (some faster than others).

- Multigrade additives are made of liquid polymers and work as thickeners to reduce the thinning of engine oil with increasing temperatures. Note that all oils thin with increasing temperatures regardless of whether they are straight oils or multigrade oils.

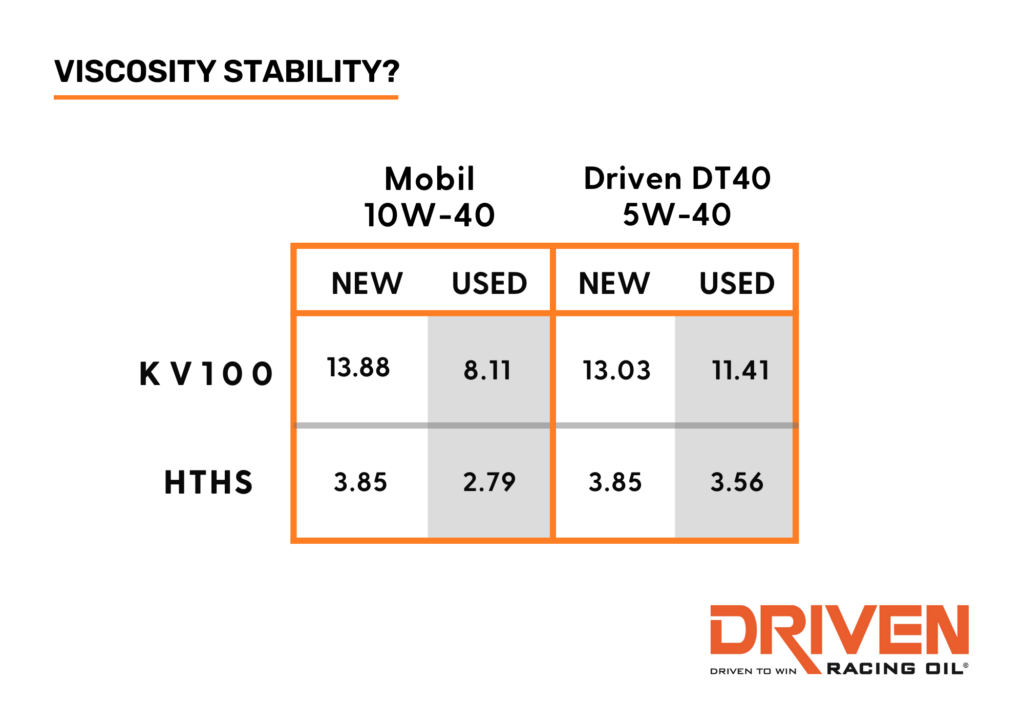

- Multigrade additives wear through shearing.

- Base oils with a higher viscosity index (VI) thin at a slower rate than those with a lower viscosity index. This means that oil with a higher VI number needs less multigrade additives. Also, different quality multigrade additives result in different levels of durability of the finished product.

- If the same base oil and the same type of multigrade additive are used for an SAE10W-40 and an SAE10W-50, the SAE10W-50 will have a bigger precentage of multigrade additives to act as an SAE50 oil at 100°C. As the multigrade additives wear this means that the SAE10W-50 will lose its viscosity rating faster when exposed to the same loads in an engine.

Conclusion: If you are choosing an oil for a racing application, it is better to choose one with a higher VI index as it will simply last longer in high-stress situations.